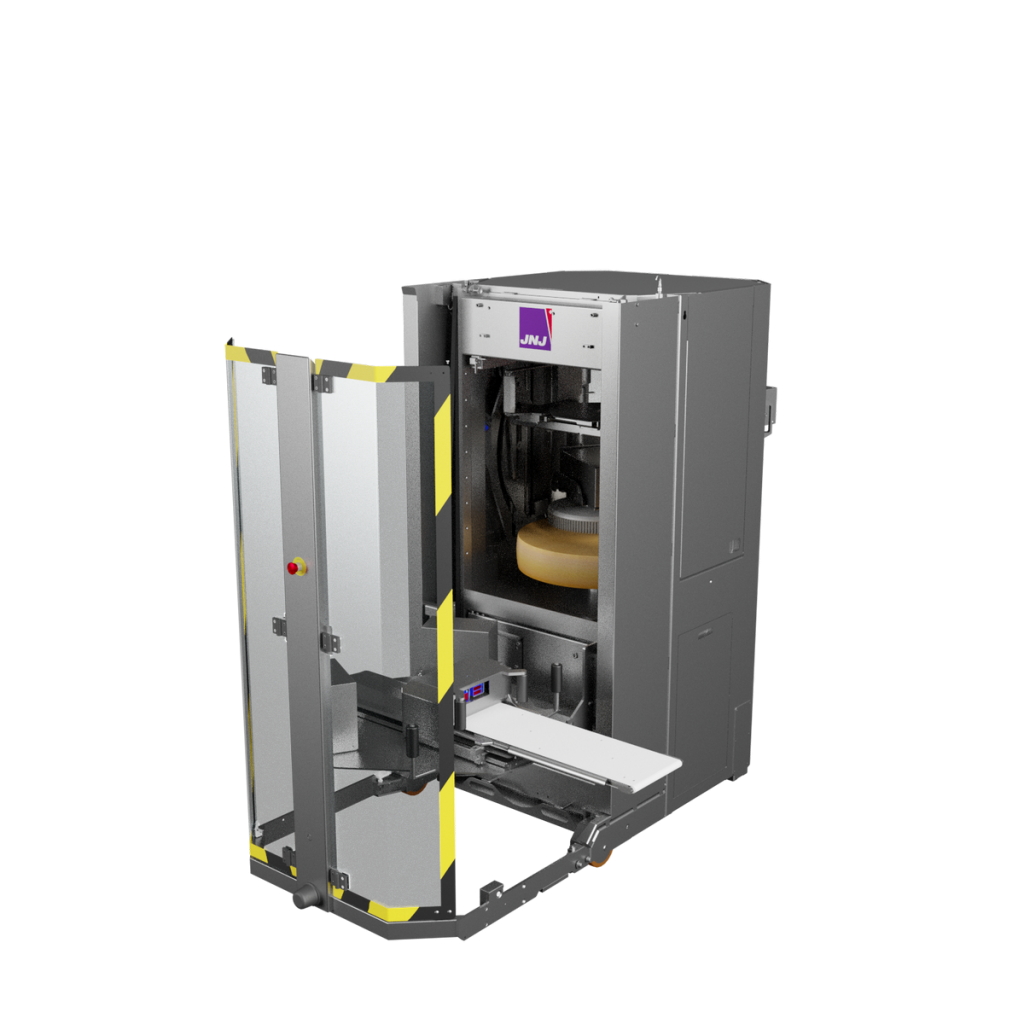

Based on the design of our RF1 robot, which was a great success for over a decade, our new RF11 robot has evolved to meet the needs of our clients.

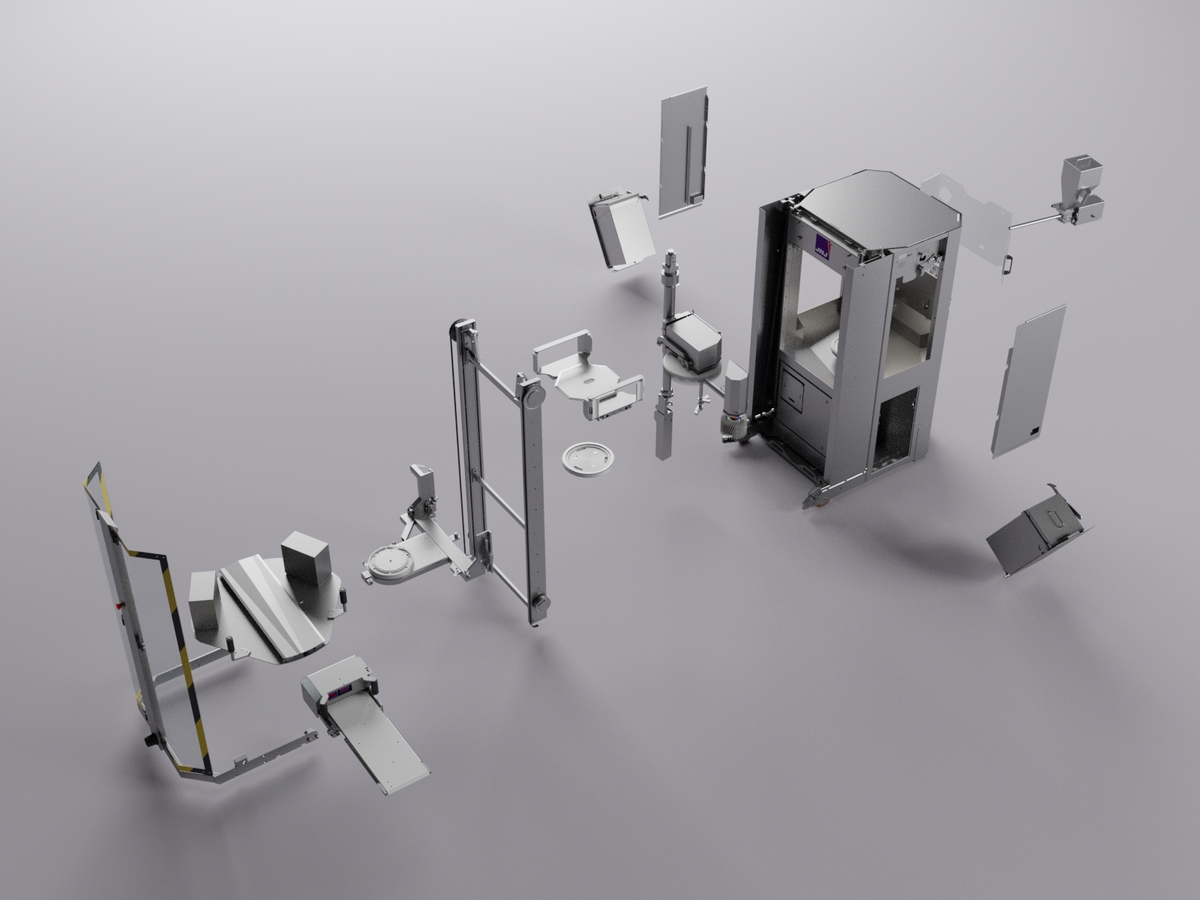

This new generation of robots combines ruggedness and versatility. With its numerous chassis variants, its integration is suitable for almost all existing cheese cellars.

His design has been revamped to optimise its routine maintenance and thus increase its useful life. The rugged and robust construction and many optional features are what makes our solution successful, and even beyond our borders.

A new generation of robots

The RF11 retains all the elements that made the RF1 such a success.

The most significant evolutions include:

- The cheese turning system has been completely redesigned.

- Movements are more fluid and the stirrups grab the cheese wheels better.

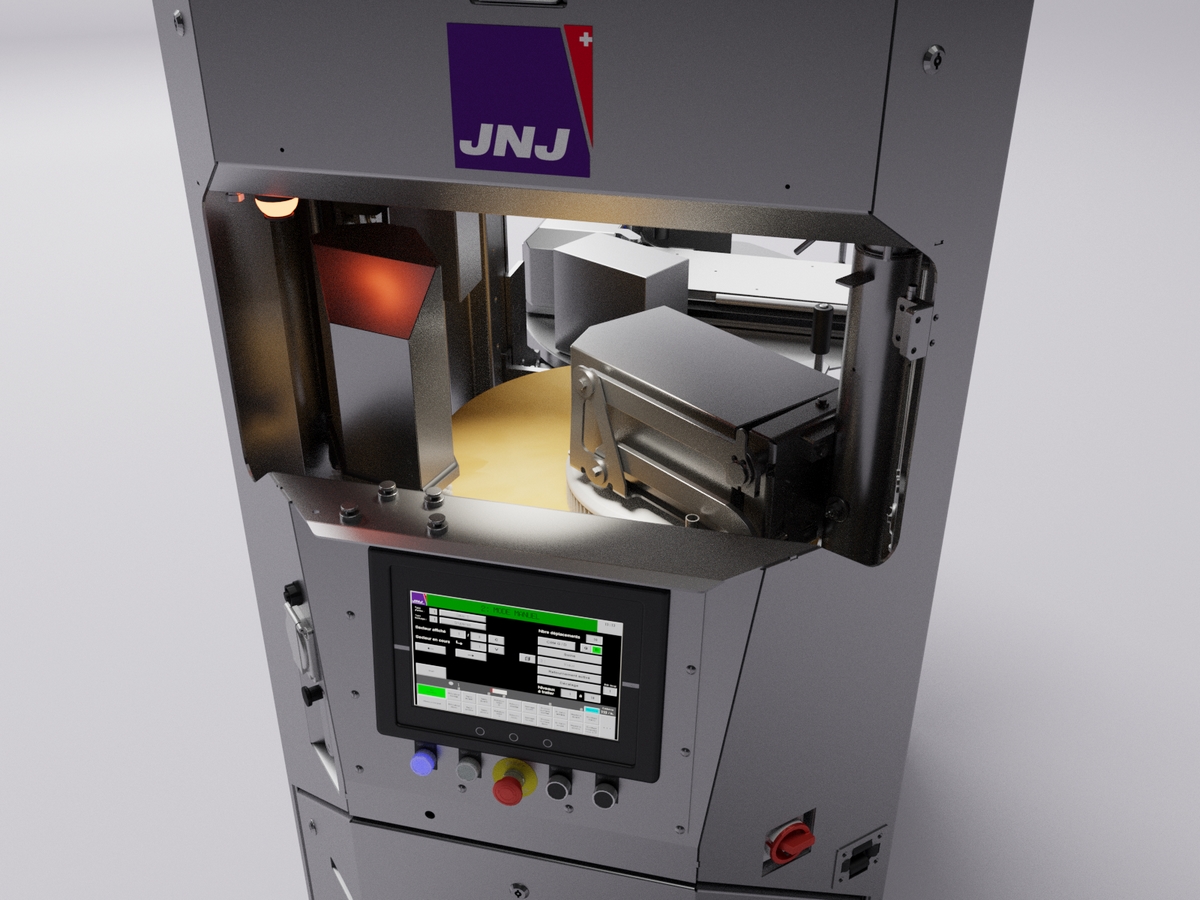

- An LED spotlight illuminates the treatment area.

- Above the chassis, there is a temporary storage area for laying down the cheese to create an offset.

- The brine tanks are made of plastic material.

- Improved hygiene of the pipes, which no longer comprise welds.

- Increased brine volume in the compact chassis.

- Improved sealing of the chassis and brushing systems.

- Removal of all hollow bodies and several design optimisations to make the system more hygienic.

- New generation of PLCs with increased memory for more scalability of future functions.

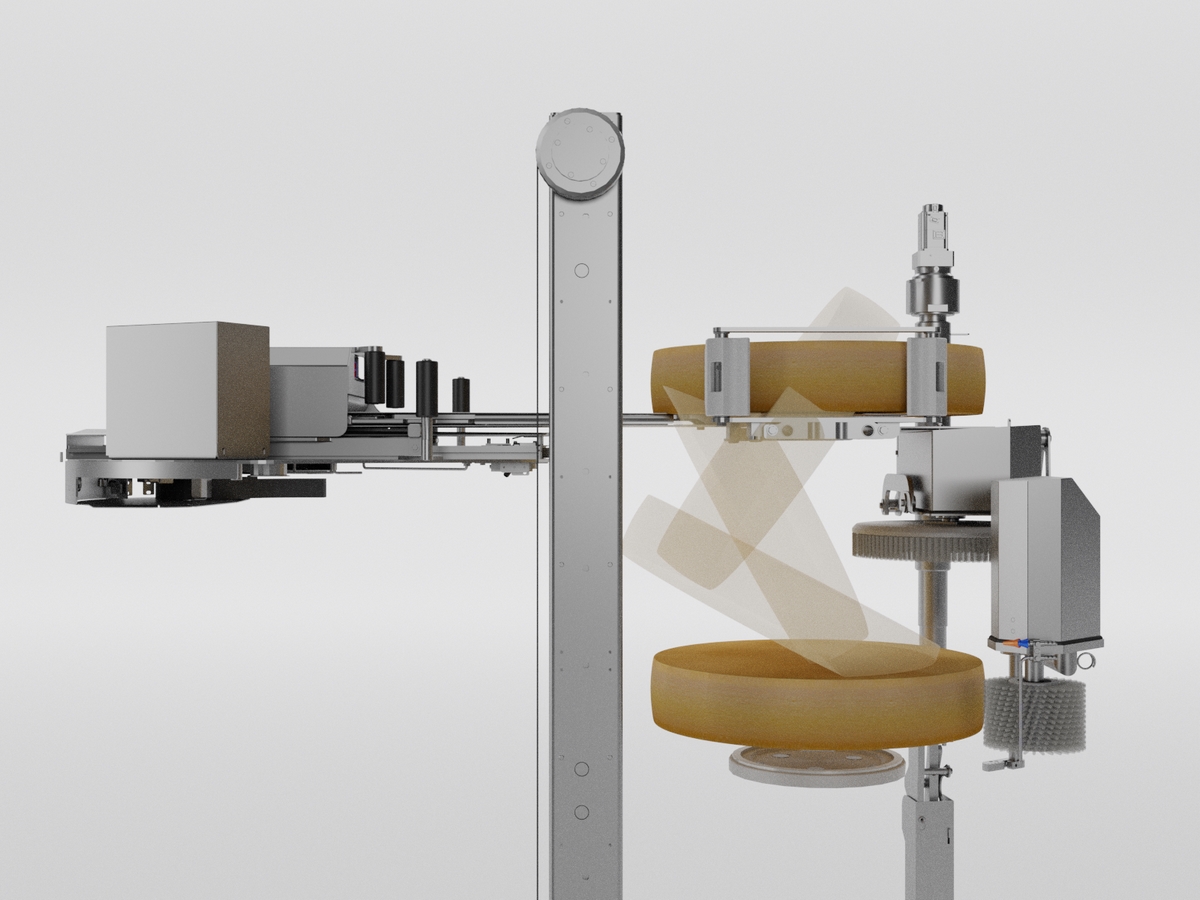

Grab Module

- Optimal pick-up of cheese wheels through efficient positional detection of the plate.

- Belt can be removed without special tools in less than one minute.

- Movement of all moving parts carried out using maintenance-free, non-stretch belts.

- Strong plastic lift and table runners, limiting wear and reducing maintenance costs.

Care

- Brushes and plate can be removed without the use of special tools.

- Large choice of brushes available.

- Brine tank level detection system.

- A LED spotlight provides good light. It can be viewed and accessed directly from the dialogue screen.

- Remote brine tank selection controls for greater accessibility.

Turning

- The kinematics of the turning module have been completely redesigned. Movements are now smoother. The cheese is held better in the turner’s stirrups.

- This new design also compacts the movement and saves space in the chassis.

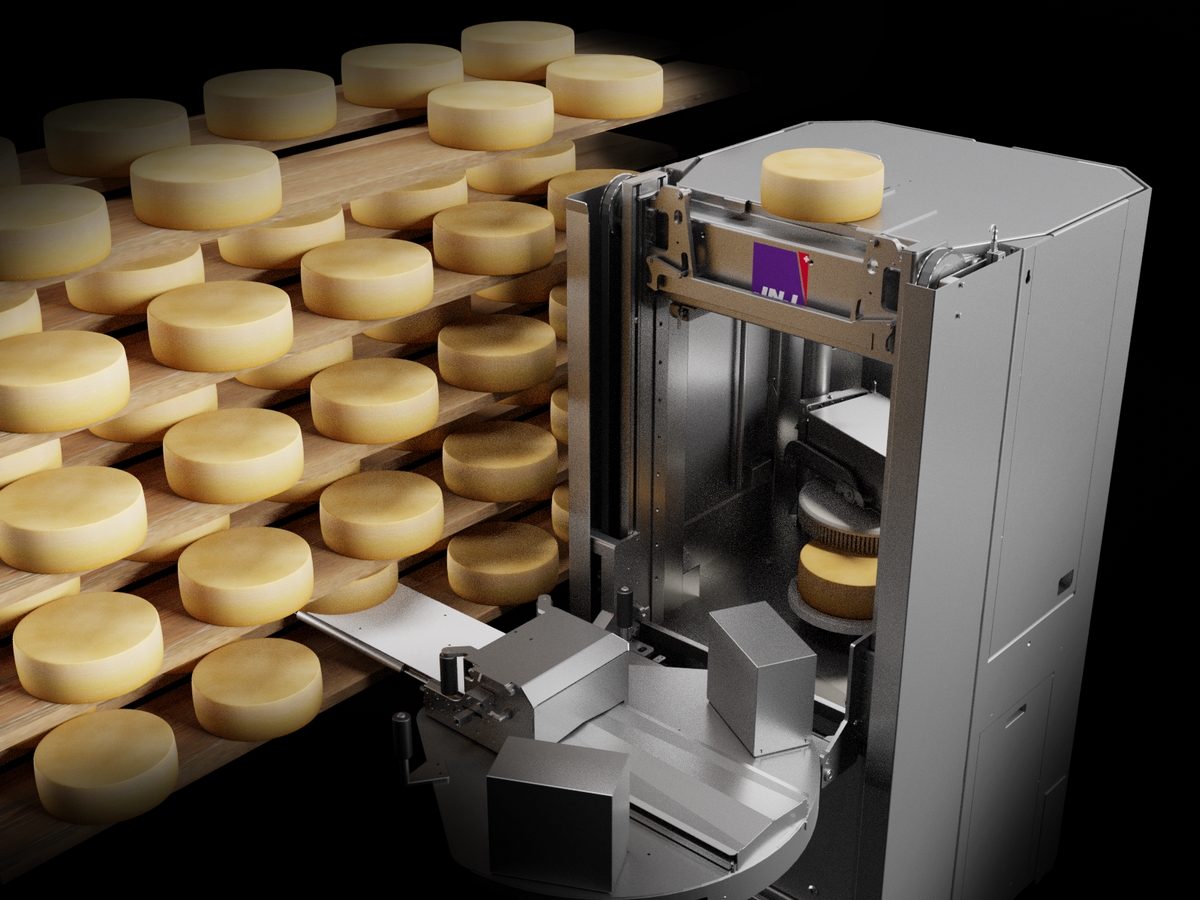

Offset programme

- The offset function is now possible with moulds arranged one behind another.

An area above the chassis can be used for the temporary storage of a cheese.

This means the grab module can free space on the rear board of another level.

Guide and movement system

- Contactless guide system : the machine moves along an aisle, automatically correcting its course.

- The robot uses the existing infrastructure and is automatically fixed on the uprights of the shelves.

- The remote control allows the operator to position itself at the best viewing angle.

- The motorised steering and steering angle that is larger than 180° allows for accurate and effortless movement.

Construction

- Single-block chassis made entirely out of mechanically welded stainless steel 1.4301.

- Hygienic : treatment station with smooth welding easily accessible.

The sloping surface enable optimum run-off of smear liquid and rising water. - Brine tanks and morge collection tanks made of plastic material, easily removable for cleaning.

- Strong, rugged construction.

Galerie de photos