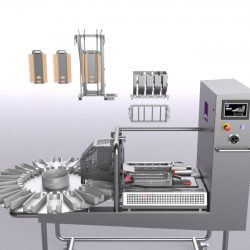

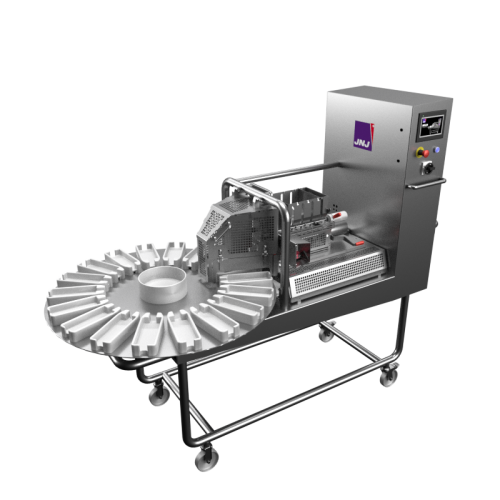

The BR110 is a semi-automatic machine with a rotating plate for producing brochettes.

Depending on the required workload and rate, the 110 cm diameter plate provides sufficient space for up to 4 operators and a rate of 30 brochettes per minute.

Compatible with several types of skewer and ingredient; the machine configuration can be modified quickly with no technical intervention required.

Overall design

- Particular care has been taken to make the machine easy to use, clean, and maintain.

- There are as few horizontal surfaces as possible to mitigate the risk of standing water.

- The tubular frame, made from stainless steel throughout, is sturdy and stable. It is fitted with 4 castors, including 2 swivel castors with brakes.

User interface

- The graphic user interface has a 7-inch colour touch screen for clear, efficient operation of the machine.

- Functionalities are accessed via several levels of user rights, depending on user accreditation.

- Production rates can be controlled by means of contactless gestures detected by optical sensors located on the side of the machine.

- Product recipes and tools can be configured to match your production requirements.

Rotating plate

- The design of the plate allows optimum surface clea-ning using a high-pressure jet. The 18 sliders ar-ranged round the machine enable swift removal of all accessories.

- The central bowl can be used to hold small, additional ingredients to be skewered, such as bell peppers and tomatoes.

Tooling & cannon

- An automatic verification system controls the proper alignment of the equipment. The system does not start if any inconsistency is detected.

- The compact design of the mechanism facilitates cleaning around the components and provides quick access to mechanical settings.

- The distributor features an automatic unclogging system: this results in far fewer disruptions due to defective skewers.

- Each loader is specifically tailored to a certain type of skewer. Loaders can be changed quickly, with no tools required.

- Cartridges for gun shaped skewers can be prepared in advance and inserted alternatively in the loader during production. This feature avoids downtime while skewers are reloaded.

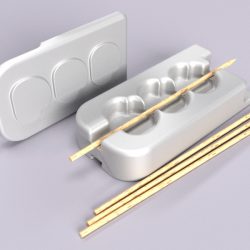

Dies

- The made-to-measure dies for your product selection are machined using EC 1935/2004 compliant synthetic materials (EU food contact regulation).

- The dies are shaped so as to have no sharp angles, preventing the product from building up in the corners, ensuring seamless production, and minimising downtime.

- The dies can easily be cleaned in an industrial dishwasher.

Photo gallery