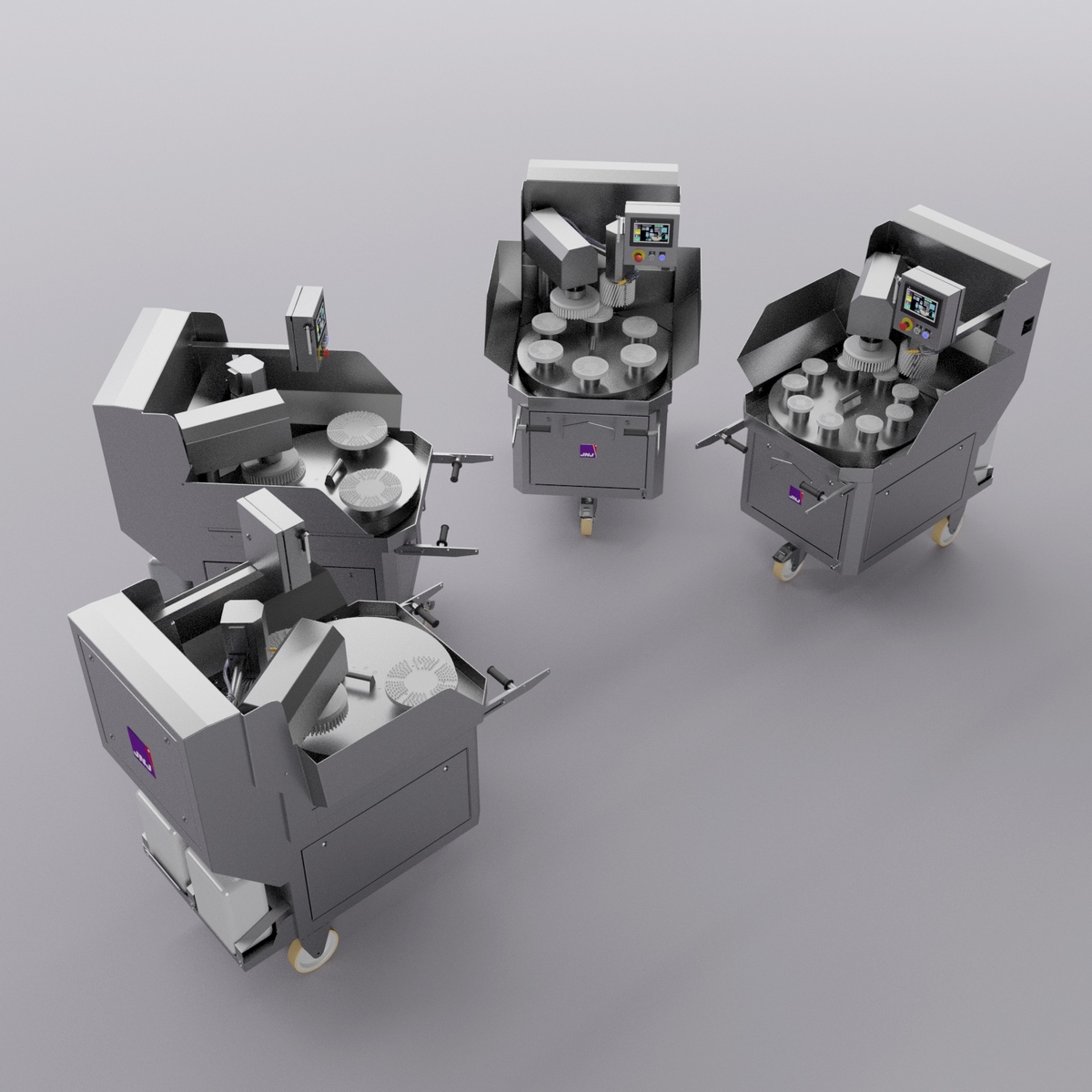

The MF1 is the ideal solution in addition to automated cellars and for the care of small, dedicated series. The new generation has been completely upgraded, delivering more flexibility and a wider range of applications.

You can be sure of benefitting from a reliable, tried and tested machine for many years to come.

Overall design

- The easy-access care station has been designed to our ‘Hygienic Design’ specifications.

- The highly compact chassis is mounted on three large-diameter wheels, making it easy to move over thresholds. The pivoting front wheel can be locked once the machine is in position.

- A range of carousels are available for use with various sizes of cheese, with 2 to 9 care trays.

- The working height of the care trays is 100 cm.

Construction

- Sturdy, durable construction with a mechanically-welded one-piece chassis, 1.4301 stainless steel throughout.

- Hygienic : the care system features smooth welds and is easily accessible. The inclined surface allows optimum drainage of spent brine and cleaning water.

- Tool-free removal of the carousel, trays, brushes, and side protectors, simplifying cleaning operations.

- Board holders swivel, saving space when storing the machine.

Care

- Range of brushes and trays available.

- The pressure of the top brush can be adjusted electronically ; the side brush has a manual tension system.

- Multi-tray carousel system gives operators time and room to handle cheese properly both before and after treatment.

- After the cheese has been placed on the intake tray, treatment is automated through to the output at the end of the cycle.

- Cheese detection sensor controls the care process and spraying.

Tanks & Pumps

- Two peristaltic pumps independently supply the sprin-kler systems on the side and top of the cheese, can be configured separately for each recipe.

- Two light, easy-to-clean 16-litre tanks : one to hold brine, the other to collect smear. Inexpensive to re-place.

- To ensure perfect hygiene, the brine supply circuit comprises a single tube made from food-grade silicone, running from the tank to the sprinkler nozzle.

User interface

- Fitted on a stainless steel bracket, the control panel allows the machine to be operated without cluttering up the workspace.

- The machine is operated using physical controls and a colour touchscreen.

- The modern, user-friendly graphic interface makes operating the machine easy and intuitive.

- Use of the interface is facilitated by a reversible pen ; this also protects the screen from dirt.

Settings

- A programmable logic controller allows settings and can save a large number of parameters. All the care settings can thus be saved in recipes :

- Care time

- Top brush pressure

- Side, and top brush rotation speed as well as tray speed

- Number and duration of side and surface brine pump strokes

Presentation film

Photo gallery