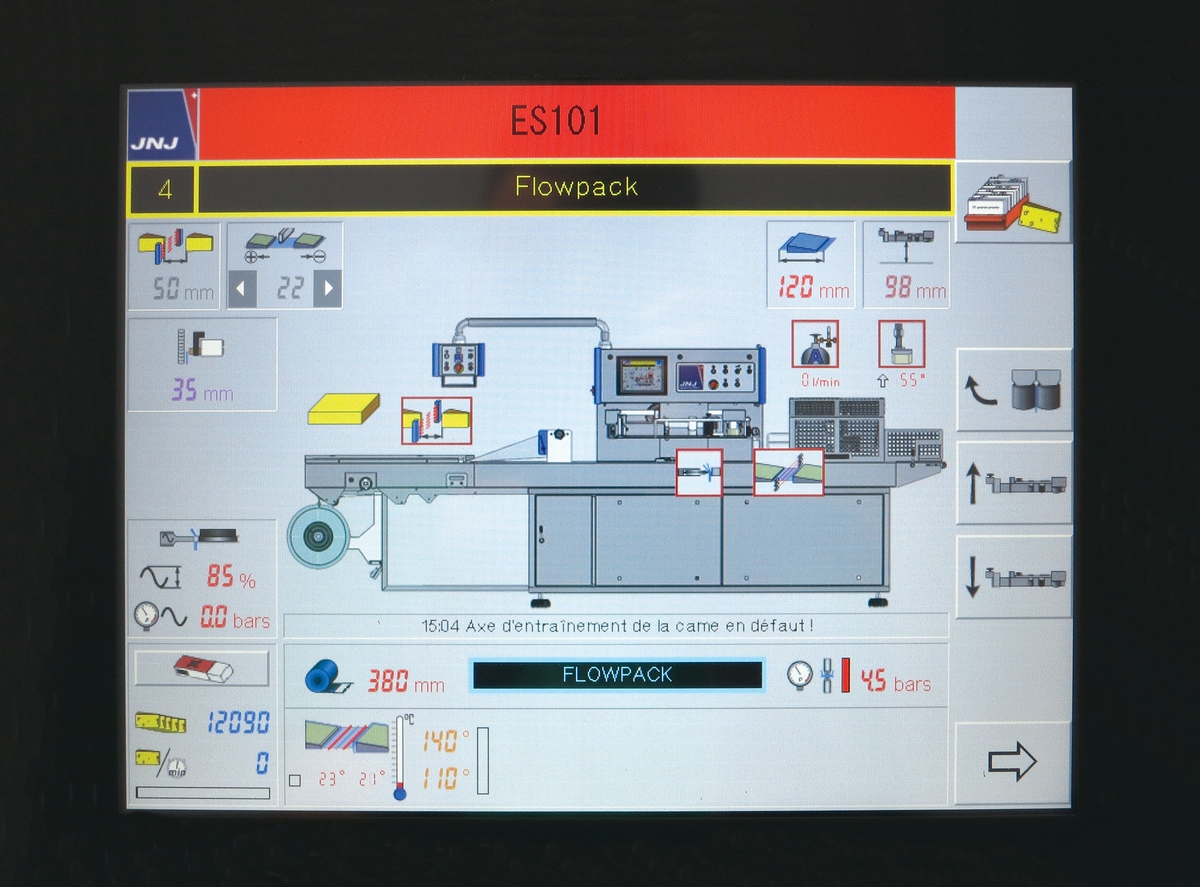

Versatile and flexible, the ES101 wrapper is the result of many years of experience of our company in the HFFS field (horizontal-form-fill-seal). Compatible with both shrink film (protection or barrier) with laminated films, it requires less than 10 minutes for a

complete configuration change over.

The longitudinal ultrasonic sealing system allows sealing without alteration retractable or laminated film, this with a very low power consumption (20 watts).

The visual appearance of the resulting seal ensures a unique presentation of packages.

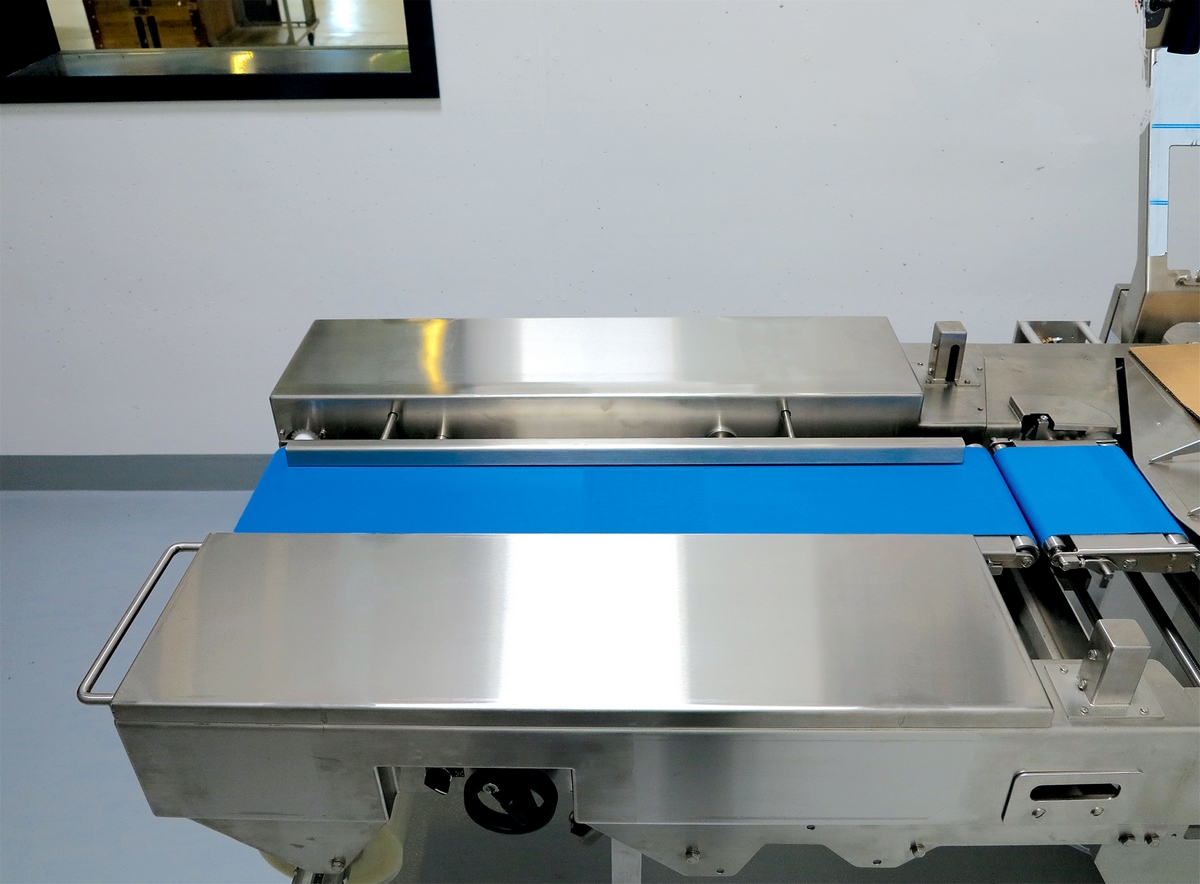

Infeed conveyor

- Ensures product positioning at a regular and controlled distance.

- Minimizes both film loss and operating costs.

- Easily removable for cleaning.

- Many detection types available to optimize the posi-tioning depending on the shape of product.

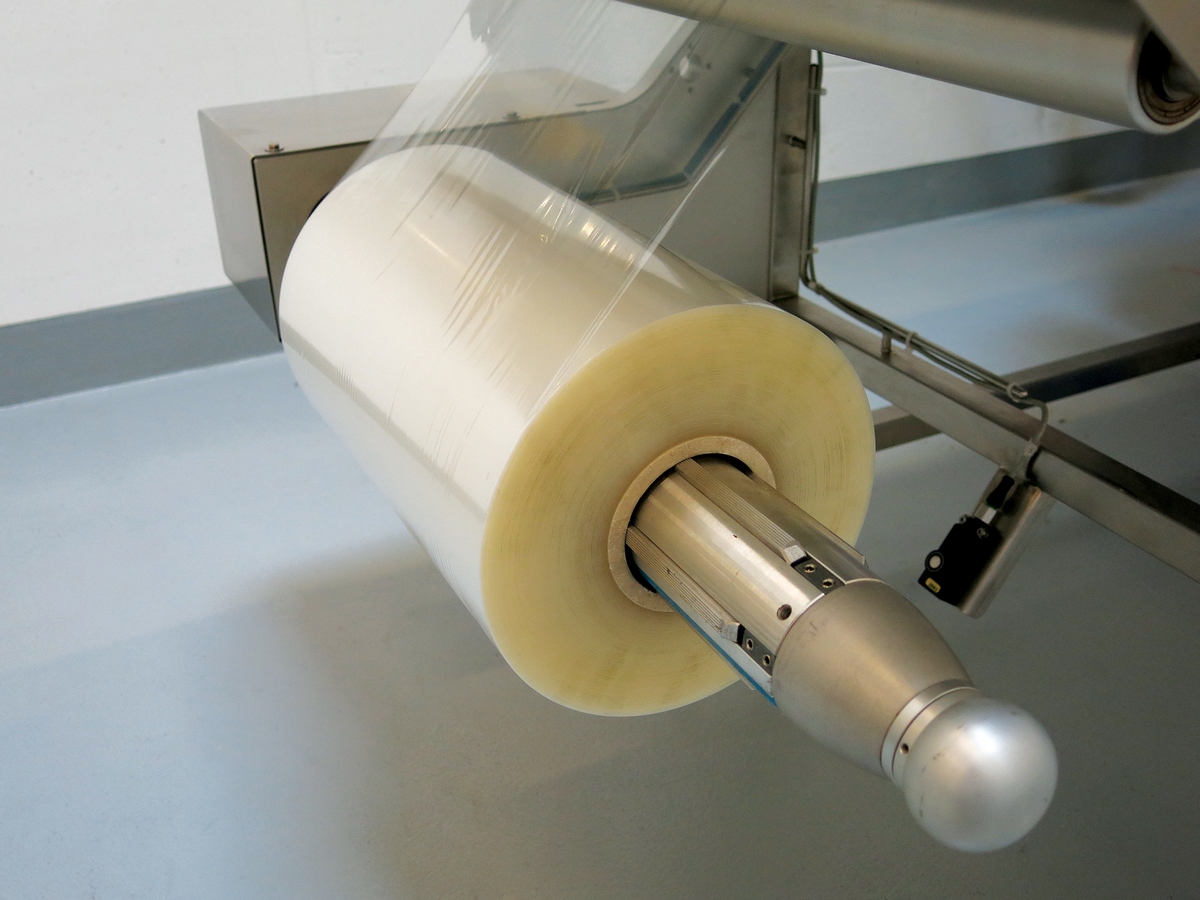

Film

- Protective or barrier shrink film.

- Laminate film.

- For variable shapes and sizes portions.

- Electrical and adaptive reel holder brake.

- Integrated waste collector.

- Shrinking by a oven from JNJ type FRXXX (optional).

Shaper

- Automatic vertical positioning depending on the se-lected product.

- Edges height of the film correcting system.

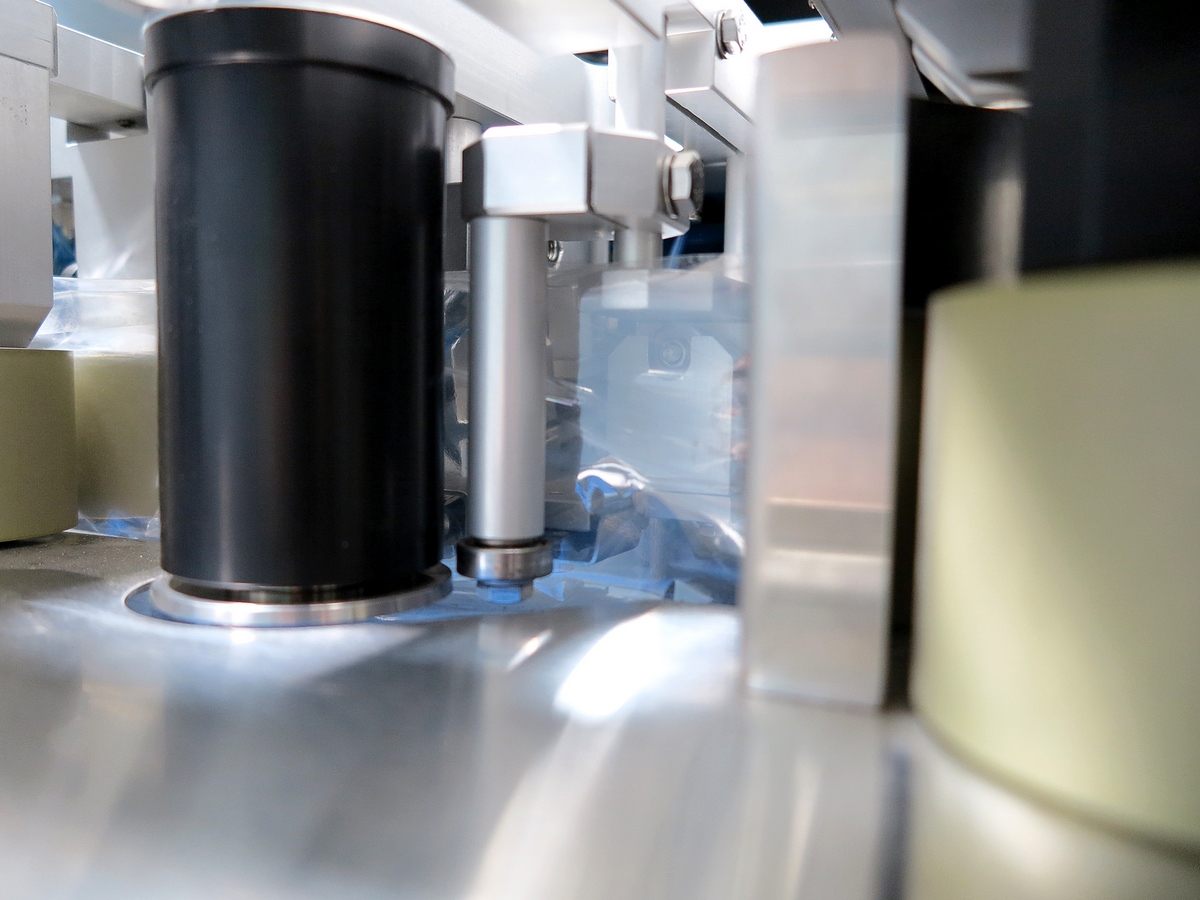

Longitudinal ultrasonic seal

- Allows the sealing of a shrink film without altering.

- Shrink film sealing width : 0,3-0,4 mm.

- Laminated film sealing width : 1,5-2 mm depending on application.

- No fouling of the sealing system : the film does not melt when stopping.

- With or without waste cutting.

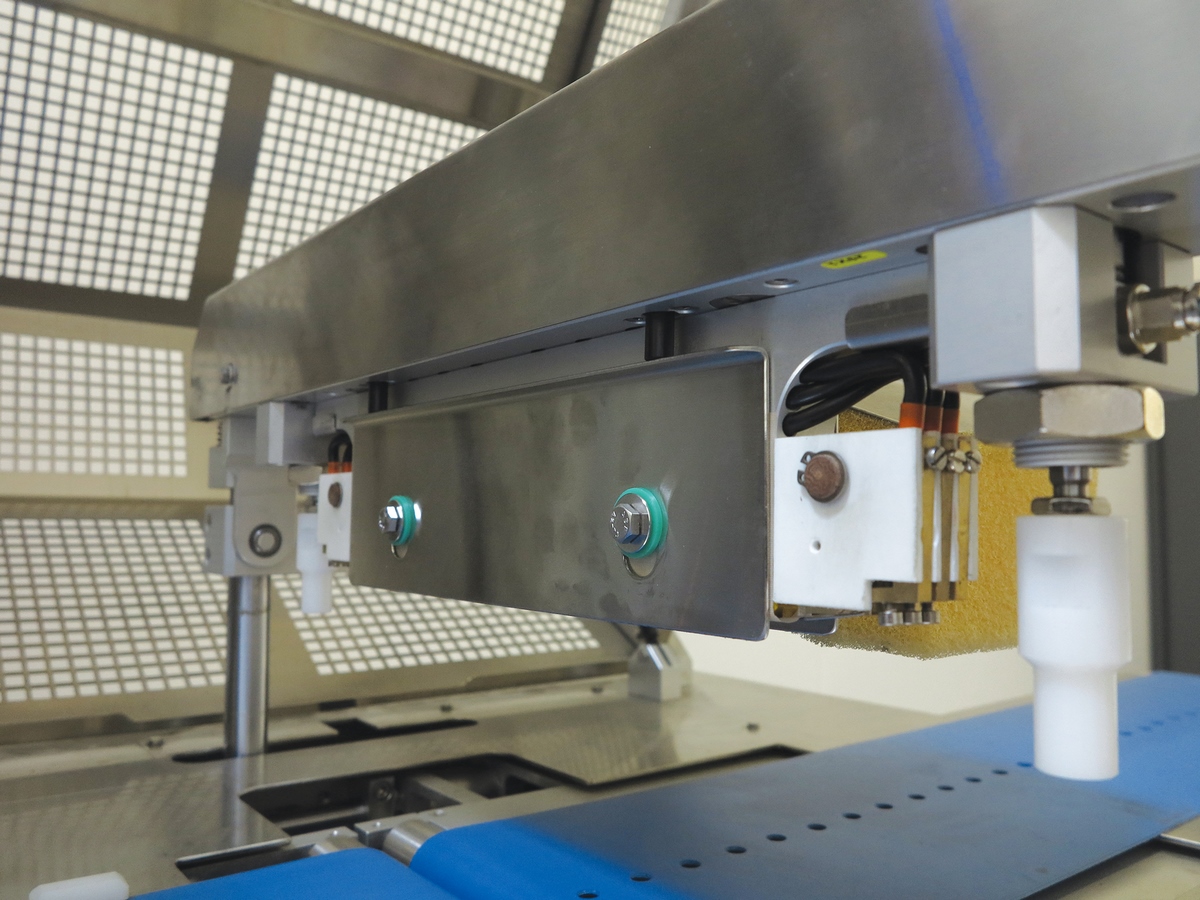

Cross thermal seal

- Very precise pulse heating system.

- Dynamic controller without inertia.

- Water cooled jaws.

- Quick release sealing jaws.

User interface

- 12’’ colour screen for a comfortable use.

- Many illustration for more clarity.

- Up to 50 product recipes available.

- Automatic adjustment of the settings depending on the selected product.

- Allows control and storage of settings of the «FR» range shrink tunnel downstream.

Presentation film

Photo gallery